FreeD Printing

Real 3D Printing

Our Mission

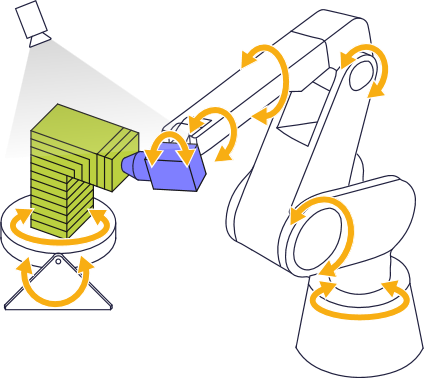

Additive manufacturing processes offer new possibilities for the production of parts compared to conventional manufacturing processes. However, due to limitations of the common modeling pattern, many of the additive manufacturing systems do not use the full potential that the additive manufacturing processes basically offer. Our modeling method FreeD Printing revolutionizes the modeling pattern of many additive manufacturing processes by using a six-axis robot in the modeling process.

The technology

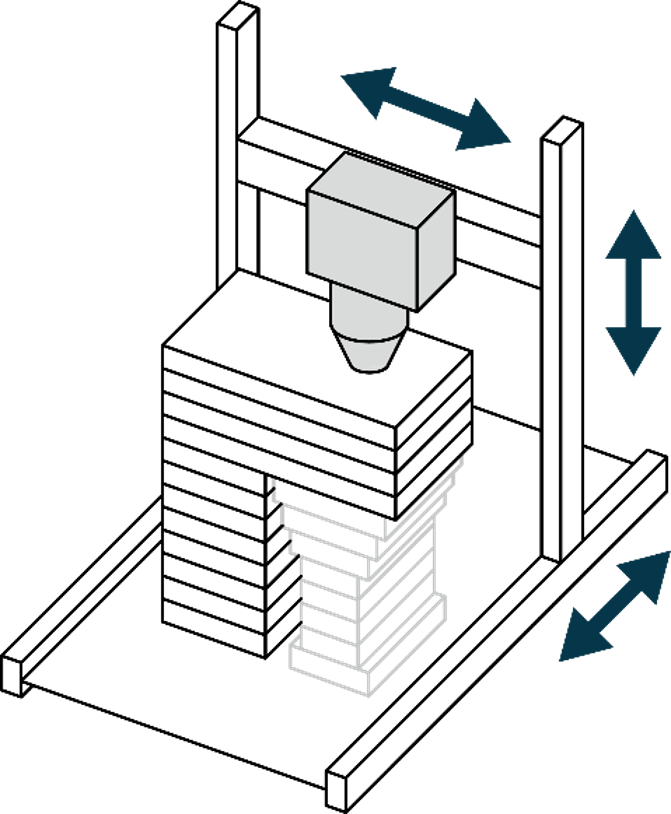

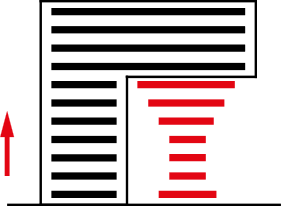

Today's modeling process

- from bottom to top - unidirectional

- planar layers

- horizontal layers

FreeD Printing

- variable modeling directions - multidirectional

- Free formed layers

Kinematic limitations of many additive manufacturing systems lead to a common modeling pattern, where the model build-up is done with planar and horizontally aligned layers. By using a six-axis robot, model build-up with FreeD Printing is more flexible and thus creates fundamentally new possibilities for industrial production with additive manufacturing processes.

The advantages

Today’s common modeling pattern has significant drawbacks:

- Component overhangs increase the manufacturing effort due to the required production of additional support structures and their final removal as a finishing operation

- Modeling is usually possible only on flat surfaces

- The modeling pattern defines main component properties like the strength and the surface quality

The multidirectional FreeD Printing modeling process thus offers new possibilities and significant advantages for industrial production of components with new improved properties.

Reduction of support structures

- Reduction of planning process and manufacturing time

- Savings in production materials

- No postprocessing

Modeling on curved surfaces

- Modeling on and around existing objects

- New use cases for repairs and customization

Combination of layer orientations

- Optimization of component properties

- Strength

- Surface quality

Additive manufacturing with FreeD Printing

Printing services

Flexible

Manufacture even complex components without the limitations of other additive or conventional manufacturing systems and processes

Effizient

Reduced costs due to the saving of manufacturing effort (time, and resources)

Large format printing

Produce large components by utilizing the working range of the applicable robot

You too can benefit from the advantages and new production possibilities that FreeD Printing offers for the manufacture of industrial components. Based on your product idea or a 3D model, we define the requirements together with you and develop an optimal strategy for the implementation of your project. Contact us and receive your individual offer.

Modular manufacturing systems

In addition to the production benefits listed, users of the technology will benefit from these advantages:

Modularity

Customer-specific problem solutions for the manufacturing tasks by selecting the required system, process and software modules

Range of materials

Extendability to different additive manufacturing processes (LMD and WAAM) and materials (metals and high-performance plastics)

Production costs

Reduction of production costs due to lower manufacturing effort (time, resources, etc.)

Large format printing

Produce large components by using a robot with a large installation space

Our Startup History

09/2017 – 05/2019

06/2019 – 08/2020